Basic Info.

Model NO.

RTPM-2015009

Application

Household Appliances, Commodity, Home Use

Runner

Cold Runner

Design Software

UG

Installation

Fixed

Certification

TS16949, ISO

Standard

PUNCH

Customized

Customized

After-sales Service

1 Year

Core Steel

2738h

Cycle Time

48s

Custom Logo

Yes

Material

Plastic

Transport Package

Wooden Box

Specification

CE/SGS/ISG

Trademark

Rootsino

Origin

Qingdao, Shandong

HS Code

8480719090

Production Capacity

400 Sets/Year

Product Description

Rootsino are professional Plastic Injection Mould Manufacturer who have more than 16 years experience, specializing in Plastic Injection Mould with Cold&Hot Runner/Gas Assistant Mould/High Glossy Mould/2K Injection Mould/IML/Stack Mould,you can get one stop plastic products service here.

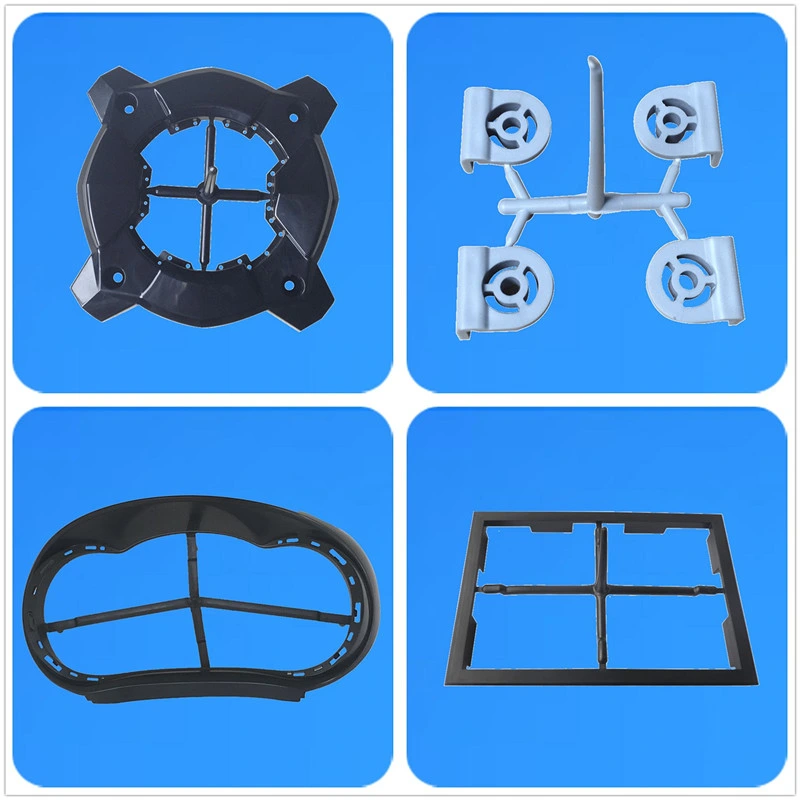

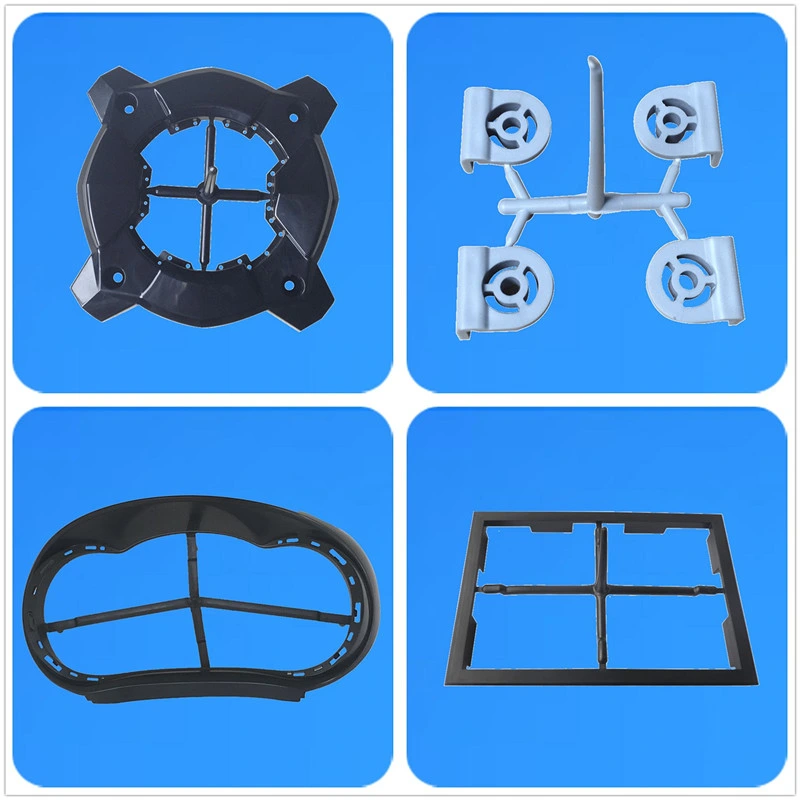

Product show

Mould Show

Mould Show

Mould Factory Show

Mould Factory Show

Injection Factory Show

Injection Factory Show  Advantage:

Advantage:

1. Specialize in Automotive mold/household mold/Electrnoic product mold about 16 years.

2. High quality & competitive price & professional skills.

3. In house strict quality control.

4. Fast and on time delivery because have our own factory.

5. All mold could be produced automatically depend on your design.

6. Our own factory that can control the delivery time well.

7. Customized service and can help improve design.

Offered Service:

1. Mold progress report and tooling schedule will be provided weekly.

2. The first testing sample for buyer's inspection and work out improvement requirements will be provided.

3. Mold testing video, 2D part drawing and 3D mold design before shipment will be provided.

4. Help integrate work.

Specification:

Part Material: PC/PP/PBT/ABS/PMMA/PU/PE/PVC

Core &Cavity Steel: P20/H13//GS2344/NAK80/ASSAB718H/ASSAB8407

Mold Base Steel: P20/1050/S50C/

Runner: Hot or Cold

Runner

Gate Type: Sprue Gate/Pin Point Gate/Edge Gate/Submarine Gate/Fan Gate/Ring Gate

Cavity No: Single or Multiple.

Mold Base Standard: DME/LKM/HASCO/etc.

Spare Parts Standard: DME/HASCO/DAIDO/MISUMI/Customized is acceptable.

Mold Life: 30k-1, 000 k

Cycle Time: 10-120 s

Lead Time: 30-45 days

Injection Machine: 50-1200 Ton

Updated on 23/12/28

Product show

Mould Show

Mould Show  Mould Factory Show

Mould Factory Show  Injection Factory Show

Injection Factory Show  Advantage:

Advantage:1. Specialize in Automotive mold/household mold/Electrnoic product mold about 16 years.

2. High quality & competitive price & professional skills.

3. In house strict quality control.

4. Fast and on time delivery because have our own factory.

5. All mold could be produced automatically depend on your design.

6. Our own factory that can control the delivery time well.

7. Customized service and can help improve design.

Offered Service:

1. Mold progress report and tooling schedule will be provided weekly.

2. The first testing sample for buyer's inspection and work out improvement requirements will be provided.

3. Mold testing video, 2D part drawing and 3D mold design before shipment will be provided.

4. Help integrate work.

Specification:

Part Material: PC/PP/PBT/ABS/PMMA/PU/PE/PVC

Core &Cavity Steel: P20/H13//GS2344/NAK80/ASSAB718H/ASSAB8407

Mold Base Steel: P20/1050/S50C/

Runner: Hot or Cold

Runner

Gate Type: Sprue Gate/Pin Point Gate/Edge Gate/Submarine Gate/Fan Gate/Ring Gate

Cavity No: Single or Multiple.

Mold Base Standard: DME/LKM/HASCO/etc.

Spare Parts Standard: DME/HASCO/DAIDO/MISUMI/Customized is acceptable.

Mold Life: 30k-1, 000 k

Cycle Time: 10-120 s

Lead Time: 30-45 days

Injection Machine: 50-1200 Ton

| No | Equipment Name | Brand | Origial Place | Model No: | Working Stoke | Quatity |

| 1 | Wire Cutting | Sodick | Japan | AQ600L3 | 600X400 | 1 |

| 2 | Wire Cutting | Sodick | Japan | AQ360LXS | 360X250 | 1 |

| 3 | Wire Cutting | Fangzheng | China | / | 500X450 | 3 |

| 4 | EDM | Sodick | Japan | AM30LS | 320X250 | 1 |

| 5 | EDM | Jingda | Taiwan | D350 | 350X250 | 2 |

| 6 | EDM | Qunji | Taiwan | QJ-345 | 400X500 | 2 |

| 7 | Milling Machine | Xuzheng | Taiwan | / | 600X350 | 6 |

| 8 | CNC | Youhong | China | S1060 | 1000X600 | 3 |

| 9 | Polishing Machine | Zhunli | Taiwan | 618 | 350X200 | 4 |

| 10 | Polishing Machine | Yalida | Taiwan | / | 350X200 | 4 |

| 11 | Polishing Machine | Dejian | Taiwan | / | 300X500 | 1 |

| 12 | Cliper | Mitutoyo | Japan | / | 200mm | 6 |

| 13 | Micrometer | Mitutoyo | Japan | / | 200mm | 2 |

| 14 | Projector | Mitutoyo | Japan | / | 300mm | 1 |